Sampling peanuts for aflatoxins determination is based on the EU and UK Commission Regulation (EC) No. 178/2010 of 2 March 2010, amending Commission Regulation (EC) No. 401/2006 of 23 February 2006. UV-Vis Spectrophotometry methods for detection and quantification of aflatoxins in PPP are carrying out (Chandralekha et al. 2020).

Introduction

Aflatoxins are toxic compounds with the ability to cause cancer are produced predominantly by two fungal species: Aspergillus flavus and Aspergillus parasiticus. These fungal species infect cereal crops including wheat, walnut, corn, cotton, peanuts and tree nuts (Jelinek et al., 1989; Severns et al., 2003), and can lead to serious threats to human and animal health by causing various complications such as hepatotoxicity, teratogenicity, and immunotoxicity (Amaike and Keller, 2011; Kensler et al., 2011; Roze et al., 2013).

Food safety is one of the major problems currently facing around the world. Since 1985, the United States Food and Drug Administration (USFDA) have restricted the amount of mycotoxins permitted in food products. The USDA Grain and Plant Inspection Service (GPIS) have implemented a service laboratory for inspection of mycotoxins in grains. Additionally, the Food and Agricultural Organization (FAO) and World Health Organization (WHO) have recognized many toxins present in agricultural products. When mycotoxins are contaminated into foods, they cannot be destroyed by normal cooking processes. However, there have been many recent advances in food processing developed to keep final food products safe and healthy, such as hazard analysis of critical control points (HACCP) and good manufacturing practices (GMP).

Requirement of sampling

The authorized laboratories shall follow validated method of sampling based on the above EU and UK regulations and analysis for determination of aflatoxins in PPP.

Requirements of analysis

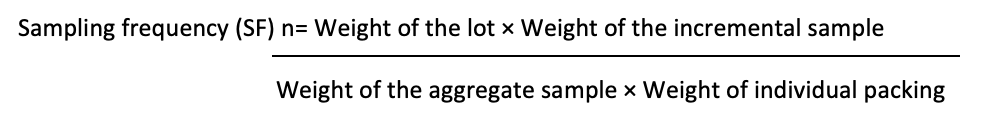

1. Commodities traded in bulk, containers, or individual packing, such as sacks, bags, retail packing. The method of sampling shall be applied to all the different forms in which the commodities are put on the market. Without prejudice to the specific provisions, following formula shall be used as a guide for the sampling of lots traded in individual packs, such as sacks, bags, retail packing.

- Weight: in kg

- Sampling frequency (SF): every nth sack or bag from which an incremental sample must be taken (decimal figures should be rounded to the nearest whole number).

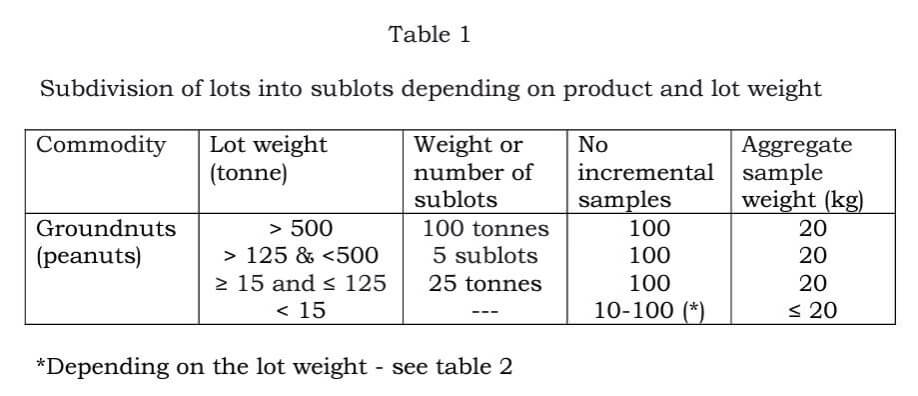

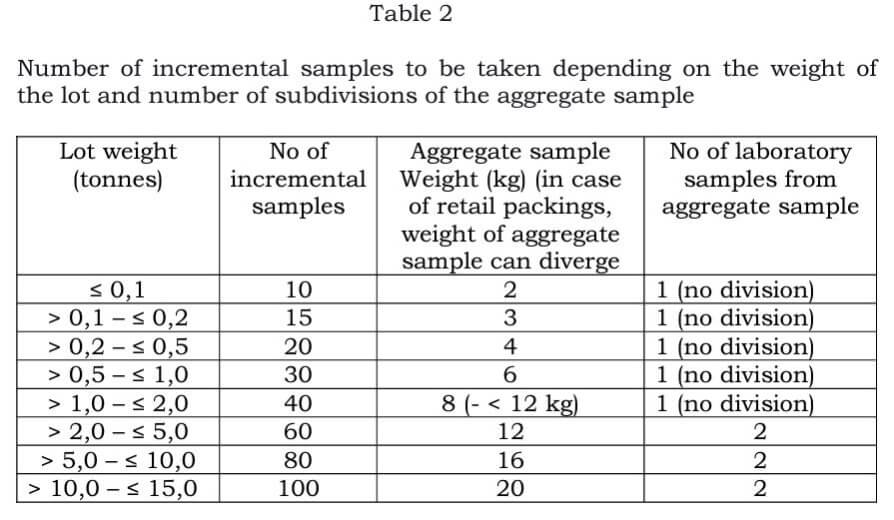

2. The sampling procedure with regards the subdivision of lots into sub lots, the number of (base) samples to be taken from the sub lot, the aggregate sample weight (kg) and the preparation of the laboratory sample.

3. For each lot, the incremental samples of peanut and peanut products from each sublot are pooled, and thoroughly mixed to yield the aggregate sample.

4. The required number of (base) samples can be obtained in the following manner, with the objective of acquiring a representative collective sample:

(i) Automated sampler for filling individual packages

(ii) Samples of at least 100 different individual packages (=< 50kg)

(iii) Samples taken from all big bags

5. Wet grinding is performed by mixing and blending samples and water or extraction solvents together (Kai Zhang et al. 2020)

6. UV-Visible Spectroscopy in the range of 350 nm to 850 nm range is used in the determination and quantification of aflatoxin in test samples.

General survey of the method of sampling

Conclusion

Aflatoxins are a major source of disease outbreaks due to a lack of knowledge and consumption of contaminated food and feed worldwide. Excessive levels of aflatoxins in food of non-industrialized countries are of major concern. Several effective physical, chemical, biological, and genetic engineering techniques have been employed for the mitigation, effective control and management of aflatoxins in food. However, developing fungal resistant and insect resistant hybrids/crops to combat pre-harvest infections and their outcome is a major issue of concern.

Peanuts reporting aflatoxin levels of more than 2 µg/kg for B1 and more than 4 µg/kg sum of B1+B2+G1+G2 in one representative analyte shall not qualify for export and direct human consumption or as an ingredient in foodstuffs, with the exception of crude vegetable oils destined for refining and refined vegetable oils category.

Peanuts reporting aflatoxin levels of more than 8 µg /kg for B1 and more than 15 µg/kg sum of B1+B2+G1+G2 in one representative analyte shall not qualify for export and subjected to sorting or other physical treatment or further processing, before human consumption or use as an ingredient in foodstuffs with the exception of groundnuts (peanuts) for crushing for refined vegetable oil production.

Peanuts reporting aflatoxin levels of more than the limits of aflatoxins of importing country in µg/kg for B1 and B1+B2+G1+G2 in one representative analyte shall not intended for direct usage as nutrient dietary for animal and bird consumption or use as an ingredient in feeding product.

Reference

Trade Notice No: APEDA/Q/2010 Dated: 6th September 2010 (Revised on 24.11.2010)

Key words

Peanut, Aflatoxin, Sampling, UV-Vis Spectroscopy, Apeda, EU and UK regulation

Key Takeaways

• Aflatoxin level more than 2 µg/kg for B1 and more than 4 µg/kg sum of B1+B2+G1+G2 shall not qualify for export and direct human consumption.

• Aflatoxin level more than 2 µg/kg for B1 and more than 4 µg/kg sum of B1+B2+G1+G2 shall not qualify for export and subjected to sorting or other physical treatment or further processing, before human consumption.

• Aflatoxin levels of more than the limits of aflatoxins of importing country in µg/kg for B1 and B1+B2+G1+G2 in one representative analyte shall not intended for direct usage as nutrient dietary for animal and bird consumption or use as an ingredient in feeding product.